Rocking Mode Analysis (RMA)

Features and Benefits

- Solve rub&buzz problems

- Optimize speaker stability for more output

- Find the dominant root cause for rocking

- Capture imbalances in mass, stiffness, BI

- Locate them on the diaphragm

- Detect systematic errors

- Fast laser scan <10 min

- All important results on a single page

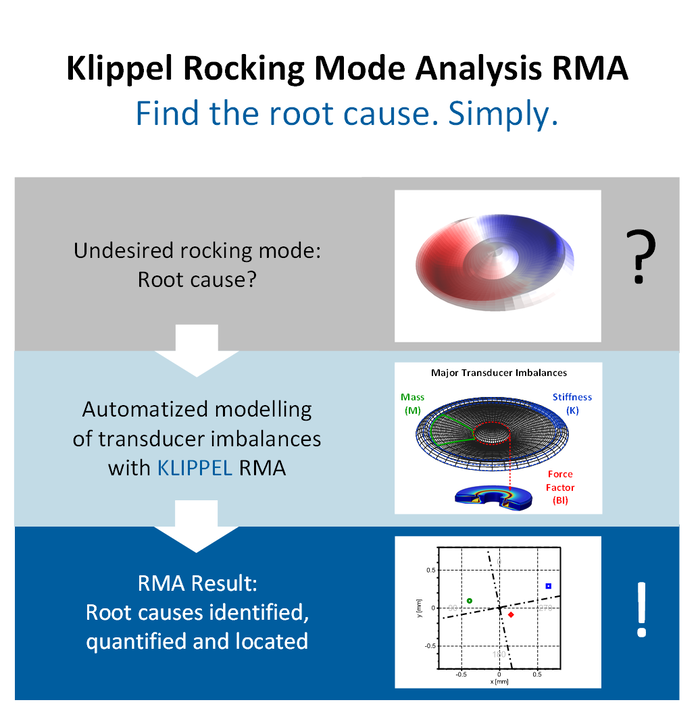

For microspeakers, headphone drivers and other transducer types with thin build and simple suspension designs, rocking modes are a common problem. These undesired tilting resonances of the diaphragm appear often in the low end of the passband where they affect the stability of the driver during bass reproduction: Due to the very low damping of rocking modes, already tiny inhomogeneities in the design can trigger large tilting angles, which can force the voice coil to hit the boundaries of the magnetic gap. This will dramatically reduce life-time of the speaker and deteriorate the allowable output and perceived quality of the product due to excessive impulsive distortion.

The Rocking Mode Analysis (RMA) is designed to provide the necessary diagnostics to solve such problems. Using distributed vibration data measured by laser vibrometry (Klippel Laser Scanner System (SCN) or Polytec LDV through POLY2SCN ), it separates the undesired rocking modes from the desired piston mode.

RMA identifies the root-causes for the rocking: Imbalances in the distributions of mass, stiffness and electromagnetic force factor. It quantifies their excitation forces, ranks them in order of magnitude and shows where the geometrical center for each of these imbalances is located on the diaphragm. With this information available, weak points in the design and in the manufacturing, process can be unveiled with great benefits for the performance and reliability of the speaker.

Specification

Demo Video

Introduction Rocking Mode Analysis (RMA)

With loading this video, you agree that your data will be transferred to YouTube and that you have read our data protection policy.

What's New in dB-Lab 212: Rocking Mode Analysis (RMA)

With loading this video, you agree that your data will be transferred to YouTube and that you have read our data protection policy.

Requirements

Test Hardware

Modules

License Dongle (USB)

Application Note

Releted Information

Other Modules of the R&D System

- Higher Modal Analysis (HMA):

Automatic extraction of modal parameters of loudspeaker diaphragms